Multi-Region Segmentation Based on Compact Shape Prior

IEEE Transactions on Automation Science and Engineering, IEEE Computer Society, 2015, 12(3): 1047-1058.

Ran Fan, Xiaogang Jin, and Charlie C. L. Wang

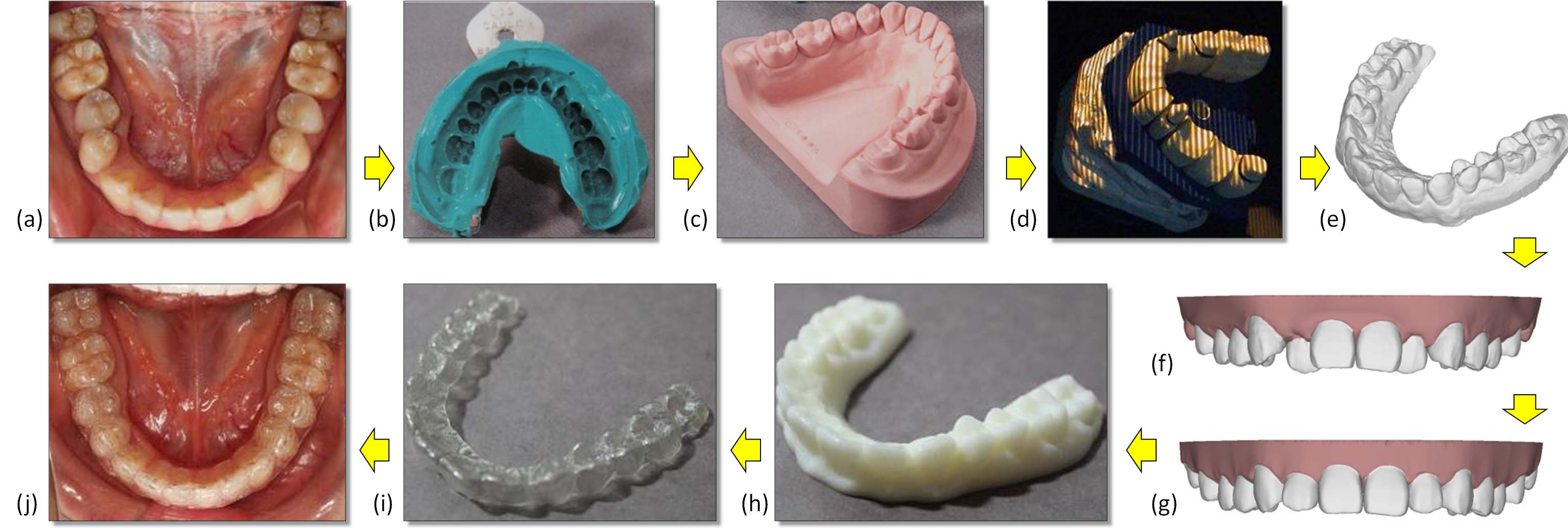

Our segmentation technique plays an important role

in the application of designing customized orthodontic braces for a

patient’s misaligned teeth (a). As the first step, a dental impression

(b) is made by placing elastic impression material into the patient’s

mouth. After that, plaster is used to create a dental model (c) from the

impression, and the dental model is scanned by a structure-light-based

scanner (d) resulting in a digital dental model (e) that is represented

by a surface mesh. With the help of our approach, the surface mesh is

segmented into the crowns of teeth and the gum (f). New arrangement of

the teeth (as the target shape of using a orthodontic brace) can be

generated by a program according to the standard dental arc (g). The

shape of this new arrangement is then fabricated into a mould (h) by the

Fused Deposition Modeling (FDM) machine. The invisible orthodontic brace

(i) customized for this patient can finally be fabricated from this

mould by the thermal compression molding. Wearing this orthodontic

brace, dentition of the patient is corrected as shown in (j).

Abstract

To solve the problem of generating segmentations of meaningful parts from scanned models with freeform surfaces, we explore a compact shape prior based segmentation approach in this paper. Our approach is inspired by an observation that a variety of natural objects consist of meaningful components in the form of compact shape and these components with compact shape are usually separated with each other by salient features. The segmentation for multi-regions is performed in two phases in our framework. Firstly, the segmentation is taken in low-level with the help of discrete Morse complex enhanced by anisotropic filtering. Secondly, we extract components with compact shape by using agglomerative clustering to optimize the normalized cut metric, in which the affinities of boundary compatibility, 2D shape compactness and 3D shape compactness are incorporated. The practical functionality of our approach is proved by applying it to the application of customized dental treatment.

Note to Practitioners

The research work presented in this paper is to

support the procedure of customized design and manufacturing. As a very

important preprocessing step for the industrial design of many

applications, the 3D shape of real objects must be scanned and

reconstructed in computer systems. To assign semantic information to the

reconstructed mesh surface, the surface are segmented into meaningful

components which however is not a well-defined problem. There is no

general segmentation approach that has good performance for scanned

models with freeform surfaces. According to the observation that models

in many industrial applications (e.g., customized dental treatment) have

meaningful components in the form of compact shape (e.g., teeth

separating from other regions (e.g., gum), a segmentation method is

developed in this paper by using the compact shape prior. The techniques

developed here can speedup the design and manufacturing of devices for

customized dental treatment (e.g., orthodontic braces).